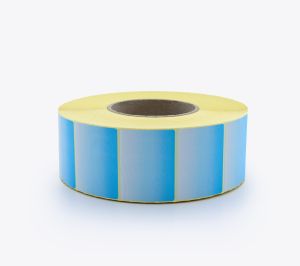

Self adhesive labels, paper

Dilcom produces self-adhesive paper labels on rolls, which are perfectly suitable for product identification in wholesale and retail, the food industry, pharmaceuticals, the cosmetic and perfume industries, transport and logistics, manufacturing enterprises, price tags, advertising and company labels, thermal labels for electronic scales Datecs, CAS and Bizerba, currier labels for printing on self-adhesive loaders, etc.

The self-adhesive labels we produce can be manufactured from many different materials (matte, semi-glossy, glossy, high-quality transfer paper) in combination with various adhesives.

We can produce self-adhesive labels of different shapes and sizes depending on your specific needs.

All of our self-adhesive labels are produced in Dilcom’s production facilities, for the manufacturing of which we use modern technologies and high-quality materials.

We offer personalised self-adhesive labels according to your requirements, brand identity and the application you need.

For more information please visit self-adhesive paper labels.

-

Price excl. tax: €12.94Price inc. tax: €15.52

-

Price excl. tax: €12.94Price inc. tax: €15.52

-

Price excl. tax: €12.59Price inc. tax: €15.11

-

Price excl. tax: €12.59Price inc. tax: €15.11

-

Price excl. tax: €10.84Price inc. tax: €13.01

-

Price excl. tax: €12.59Price inc. tax: €15.11

-

Price excl. tax: €10.84Price inc. tax: €13.01

-

Price excl. tax: €17.84Price inc. tax: €21.41

-

Price excl. tax: €20.30Price inc. tax: €24.36

-

Price excl. tax: €17.29Price inc. tax: €20.74

-

Price excl. tax: €20.86Price inc. tax: €25.03

-

Price excl. tax: €5.95Price inc. tax: €7.14